Since 1987, Fifth Avenue owner, Randy Rundle, has been making antique, classic and special interest vehicles more reliable and fun to drive. Feel free to wander around, peek in all of the corners, and spend some time reading about some of our past adventures.

12/26/18

Borg Warner R-10 &R-11 Overdrive Wiring Diagram...The Simple Version

The Borg Warner Overdrive Transmission was offered as an option by eleven different car companies. And as you might expect, each of those car companies developed their own wiring diagram for the Borg Warner Overdrive. They added extra relays, switches etc, nothing that improved or affected how the overdrive itself worked. The simplest and easiest wiring diagram to use by far... is the one developed by Borg Warner.

The picture above shows the Borg Warner overdrive wiring diagram. As you can see it is pretty simple and basic. This diagram can be used for most any Borg Warner Overdrive application.

A Few Notes -

Reverse lockout switches were discontinued by the factory somewhere around the early 1950's. They are not needed and your overdrive will work fine without one. Most original ones no longer work so just bypass the switch. You can either connect both ends of the governor wires going to the reverse lockout switch to the same terminal (which will bypass the switch) or better yet run a new wire down from the governor. Then you will never have to worry about a loose or corroded connection.

There was a recall in the early 1950's... the diameter of the wire that made up the overdrive wiring harnesses was to small in diameter causing, high resistance resulting in an excessive voltage drop and low voltage being delivered to the solenoid and relay, which in turn caused the overdrive to not work, or only work part time. The fix of course was to use larger diameter wire, resulting in less resistance and full current being delivered to the solenoid and relay. The replacement wiring harnesses were made using larger wire which fixed the problem.

So if you are building your own wiring harness I would suggest using 14 gauge wire. The cost difference is minimal and you will not have any issues with low voltage being delivered to the solenoid and relay due to resistance in the overdrive wiring harness.

Generator charging systems, (which most vehicles had that were built before 1965) have little or no output at idle and low engine rpms. So the battery current to run the overdrive at idle and low rpms (such as in town driving) will have to come from the current stored in the physical battery, which is often less that the required 6.5 volts needed to make the overdrive work properly.

You can fudge a little but if the voltage drop is too great between the battery and the solenoid (which can be caused by (electrical friction) resistance from too small of wiring) your overdrive may not engage and work properly, Or may work only at highway speeds, but will not shift in and out in city driving. Anything below 6.0 volts at the number (4) terminal on the solenoid is a sign of trouble.

Also check the voltage on the incoming side of the relay and the output side of the relay going down to the solenoid. There should be little or no voltage drop between those two terminals. A half a volt is the max, and that is if the output voltage going to the solenoid is above 6.0 volts.

You can buy a reproduction overdrive wiring harness but most are made using the smaller diameter wire. Now that you know better, making your own is easy and you know it will be done right. It will be time well spent!

11/17/18

Automotive Tires Used To Be White...It's True !

In the beginning, all automotive tires were an off white, almost a light gray in color. That is because early automotive tires were made from the milky white juice of the rubber plant. Common dandelions also produce this same juice called latex... if you snap off their stems, you can see the same milky white latex.

In theory, you could manufacture rubber by growing and harvesting dandelions, though you'd need a bunch of them. There are about 200 plants in the world that produce the same milky white colored latex used to manufacture rubber. Because of efficiency nearly all of the worlds rubber is made from the latex that comes from a tree species called Hevea Brasiliensis, which is most often referred to as a rubber tree.

The latex collected from the rubber tree is about one third water and one third latex particles held in a form known as a colloidal suspension.

Early tires made of natural rubber had thin soft sidewalls and with little to no tread pattern were subject to multiple punctures. Also traction was limited with a nearly smooth driving surface.

Along about 1910 zinc oxide was added to the natural rubber formula to give the tires more overall strength. It also took away the gray color resulting in a brighter white tire. All was good until 1914 at the start of World War I when zinc oxide was needed in the munitions industry where it was used as a propellant. The US Government required that all zinc oxide be available for the war.

Carbon Black Under A Microscope

“It wasn’t until 1912, that this ingredient was used in the manufacturing of automobile tires by the Diamond Rubber Co. of Akron, Ohio, which had acquired the rights to the use of the material from Mote’s company.

Tires without carbon black in the formula would typically last no more than 5,000 miles, while a tire with carbon black would last between 12,000 and 15,000 miles. The carbon black strengthened the sidewalls to help prevent punctures, extended the tread life by providing greater wear resistance, offered better traction, and protection from ultraviolet light damage.

By 1917 most all automobile tires were manufactured using carbon black in the formula, which changed the color of automobile tires from white to black.That of course created a huge demand for carbon black, which resulted in an unlikely alliance between two companies the B.F. Goodrich Company and the Binney and Smith Company founder of the Crayola Crayons.

B. F. Goodrich put out an order for a company that could deliver one million pounds of carbon black annually. Who answered the call...none other than the Binney and Smith Company the maker of Crayola crayons.

The Binney and Smith Company was, named after Edwin Binney and C. Harold Smith. These two, were the son and nephew, respectively, of Joseph Binney, founder of New York-based Peekskill Chemical Works, which sold charcoal and lamp black, a deep black powder obtained by collecting soot deposits from burning oil. It was used to make pigments for paint and printing inks.

Binney and Smith even made improvements to the carbon black manufacturing processes via patents including Edwin Binney’s 1890 “apparatus for the manufacture of carbon-black.” These improvements in the production process, made the production of carbon black more efficient and cost effective. The timing couldn't have been better as it matched the huge discovery of natural gas and oil in Pennsylvania.

What Is Carbon Black Anyway...?

Carbon black is the result of a hydrocarbon that has gone through incomplete combustion, and whose “smoke” has been captured as fine black particles consisting almost entirely of the element carbon. An automotive tire rubber formula is made up of 25 to 30 percent carbon black, even today. Because of demand which exceeds the natural rubber production manufactured from plants...much of the carbon black used in tire formula's today is petroleum based.

Carbon black has been manufactured in a number of different ways over the years. One of the oldest processes involves allowing a flame from an oil lamp to impinge upon a cool surface, and for the resulting powdery soot from that surface to be scraped off. That powdery soot was called lamp black, and was used in the manufacturing of paint and printing ink.

But in the 1870s, came a breakthrough called the channel process. Essentially, it involved burning natural gas up against water-cooled H-shaped metal channels, and collecting the carbon deposits. This new process, and specifically the finer particles it yielded, was an important step in yielding stronger tires for the auto industry.

Today, the primary method of obtaining carbon black is called the “furnace process,” which involves taking a heavy oil or natural gas feedstock, and injecting it into a furnace wherein natural gas and pre-heated air have combusted. The high temperatures of this reaction cause the feedstock to “crack” and turn into smoke, which is cooled by water and filtered out as tiny carbon black particles from the gas. The resulting fine powder is then formed into pellets via water and a binding agent for easier handling and transport.

The White Wall Tire...

A short time after the B. F. Goodrich Company introduced their modern up to date "Black Tire" made with the new carbon black rubber formula, a competing tire company also jumped on the carbon black bandwagon, but only added the carbon black to the tread surface, resulting in a considerable cost savings. The result? Black tread and white sidewalls.

While the white wall tire wasn't intended to be a style enhancer, it quickly caught on and other tire companies began producing purpose-built white wall tires. By the 1920's, white wall tires became a popular accessory on high end luxury cars. More conservative car manufacturers didn't adopt white wall tires as a factory option until the 1930's with Ford introducing the white wall tire option in 1934.

White walls continued to be a popular option for passenger cars, only pausing briefly for World War II and the Korean War, due to materials shortage. White walls were offered by most all of the major tire companies as an option, so you could be in style even if you didn't drive a new car, and that lead to Porta Walls...

Porta Walls...

If your budget was a little tight and you could not afford to go and buy a new set of white wall tires, but you still wanted to be in style you could order a set of Porta Walls.

Porta Walls were white rubber rings that fit under the tire bead and were glued onto the sidewall to give the appearance of a white wall tire a minimal cost. They worked... with a few minor details... the biggest one being that if you went around a corner to fast the tire would flex and the Porta Wall would come loose from under the tire bead of the tire rim...and roll out ahead of you.

Therefore it was common to buy more than one set of Porta Walls at a time, so when you lost one you had a replacement. It was not "cool" to drive around with three white wall tires and one black wall tire because everybody then knew your white walls were fake! The J. C. Whitney Company offered Porta Walls, as did most of the automotive aftermarket accessory companies of the day.

Porta Walls were a cost effective option if you were on a budget. You could get a set of Porta Walls for $3.95 vs $175.00 for a new set of White Wall tires.

The width of white walls changed over the years from the skinny half inch wide to the four inch white wall, and everything in between. Most any width is now available to match the width of white wall that was popular when your antique vehicle was new.

Your whitewall tire combination was not complete until you went by the local Standard Oil Station and got a set of the Red Crown valve stem caps, (which you can still buy today, in the "parts" section of the Fifth Avenue website). Then life was good!

You Can by these in the "parts" section of the Fifth Avenue website.

So...What Happened To All Of The Tire Manufacturers...?

Fisk - failed during the depression, was then bought by US Rubber also known as Uniroyal, which was then bought by Michelin in 1990.

Kelly Springfield was started in 1884, sold in 1935 to Goodyear, which dissolved the entity of Kelly Springfield around 1990.

Lee Tire and Rubber lasted from 1909 to 1987, bought by Kelly.

Firestone opened for business in 1900; Firestone bought Dayton Tires in 1961, the Dayco Corporation, later sued both Firestone and Goodyear, alleging that the two companies conspired to monopolize the tire industry in the United States. Firestone sold out to Bridgestone in 1988.

General Tire expanded and diversified into cold war era military subcontracting, until it was forced to sell what by now were no longer their core functions. General tire sold the tire division to German tire manufacturer Continental in the 1960's.

BF Goodrich was a subsidy of Goodrich, and was sold to Michelin in 1990. BF Goodrich was the first American tire manufacturer to make radial tires.

Goodyear was founded in 1898, and in 1999 Goodyear announced a $1-billion global alliance with Japan's Sumitomo Rubber Industries, which has rights to the Dunlop tire brand.

Cooper tires was formed around 1920, and bought Avon in 1997, then Mickey Thompson tires in 2003, and merged with Mexican tire manufacturer Corporación de Occidente SA de CV soon after.

Cooper Tire owns Avon, Dean, Eldorado, Mastercraft, Mentor Starfire, Definity, Roadmaster, Mickey Thompson, Dick Cepek, Chengshan, Austone, Fortune, Hercules and Ironman.

Hoosier tires was the last independent tire maker... but sold out to Continental tire for 140 million dollars in 2016.

As Paul Harvey used to say...." and now you know the rest of the story...."

More Tire Trivia....

Did you know that the Gates Corporation of belt and hose fame got their start making a tire accessory...? From the company's 100th anniversary book we learn...

Gates Corporation History

On October 1, 1911, Charles Gates, Sr. purchased the Colorado Tire and Leather Company located in southern Denver beside the South Platte River. Little did he know at the time that his small shop would one day become the world’s largest manufacturer of power transmission belts and a leader in hydraulic and fluid power products for industrial and automotive applications.

The Colorado Tire and Leather Company made a single product, the Durable Tread, a steel-studded band of leather that motorists attached to tires to extend their mileage. In 1917, the Company began phasing out leather in favor of rubber, and Charles Gates changed its name to the International Rubber Company.

That same year, John Gates, Charles’ brother, developed a belt made of rubber and woven threading. It was called a V-belt, due to the shape it sat in on an engine block. It replaced the standard hemp and rope belt found in automobiles and on industrial machinery, and was a model for the common serpentine belt. The belt’s success propelled the company to become the world's largest manufacturer of V-belts, a title it still holds.

And Still More....

Ohio and New Jersey were the two states were most of the tires were manufactured prior to 1925. Much like car manufacturers during the early years of the automobile, there were plenty of tire manufacturers, many who were in business for just a few years. Eventually the little companies disappeared... as they either were bought up by the larger manufacturers, or failed due to the depression or being under capitalized and not able to keep up with the technology. So here is the list...see how many you recognize.

11/13/18

What Kind Of Antifreeze To Use In Your Antique Vehicle...

It used to be simple in the old days...all of the antifreeze coolant was basically the same and varied little in price. It usually came down to what was available or what brand was on sale. Not Any More.

Now there are literally dozens of formula's and multiple colors to choose from. So what kind of modern antifreeze should you be using in you antique and more important what kind of antifreeze should you NOT be using in your antique vehicle.

First the Basics...

There are three basic antifreeze technologies in use today, they are as follows....

IAT: Inorganic Acid Technology is the traditional green colored antifreeze that is the closest formula to what antifreeze was prior to the 1980's. The lifespan of traditional coolant is about three to five years. This formula is the antifreeze we want to use in our antique vehicles.

OAT: Organic Acid Technology is used today because it offers silicate-free protection of all metals, and for a longer period of time: it’s the long life (LLC) or extended life (ELC) coolant and has a service life of five years or 150,000 miles.

Colors in the United States are mostly red and orange, but also green, pink and blue. (modern cooling systems are made up of a variety of different metals and alloys and this formula is designed to not damage the various metal alloys that make up a modern cooling system. This formula has some aggressive cleaning properties that will damage our antique vehicle cooling systems. DO NOT use an OAT formula antifreeze in your antique vehicle.

HOAT: Hybrid Organic Acid Technology. This formula is usually orange, but can also be red or yellow. This formula is a mixture of IAT and OAT, the orange cocktail – and only the orange color -- contains 10 percent recycled coolant. We need to stay away from this formula because is basically a diluted version of the OAT formula.

We need to avoid using both OAT and HOAT type antifreeze. Even though it is designed for a "longer service life" we shouldn’t use it. The OAT formula includes an inhibitor that attacks silicone compounds that are frequently used in gasket sealants. In addition, this formula also goes after lead based products like solder and Babbitt material (used in early connecting rod bearings), some yellow metals that may be in cam bearings and radiators, and conventional gasket and seal type packing materials used in some early water pumps. Your antique vehicle likely contains some, or all of these materials, so using OAT formula antifreeze will eventually result in an expensive headache down the road. You want to be using only an IAT formula antifreeze in your antique vehicle.

Many early antique vehicles have “open” cooling systems, where the radiator cap doesn’t completely seal the system. This allows for water evaporation, slowly decreasing the amount of water in the cooling system and increasing the amount of antifreeze coolant in the cooling system. The water that is mixed with the antifreeze is what evaporates which can cause you to end up with a higher concentration of antifreeze than the original 50/50 mix. That can cause engine over heating.

Around World War II, automakers began manufacturing cars with a sealed, pressurized cooling system. Not only did that stop evaporation, but for every pound of pressure built into the cooling system the boiling point of the coolant was raised by three degrees (F). As manufacturing quality improved, higher pressures became more common. By the late fifties a seven pound radiator pressure cap was common, which raised the boiling point of the coolant inside the radiator twenty one degrees.

With the addition of coolant recovery tanks in the 1960's life got even better. Now the cooling system was completely sealed from the outside air and dirt and any coolant that boiled over was caught in the coolant over flow tank, which was then drawn back into the radiator as the engine cooled. That solved the problem of air being trapped in the cooling system, and stopped the loss of coolant completely.

Cars and trucks built prior to 1950 were designed to use plain water as the coolant in the summer months and antifreeze only in the winter, in part because there was no such thing as permanent anti freeze in those days. Wood alcohol (methyl alcohol) was the first commercially available antifreeze formula, but its high rate of evaporation (if you did not drain it out in the summer months and replace it with water it would simply evaporate away...) and it's corrosive qualities led to it's eventual replacement by ethylene glycol, which was a year around antifreeze that became the standard up thru the 1980's.

Keep in mind...the antifreeze itself provides no direct cooling benefit. It is there to prevent the water from freezing, and to keep the inside of the cooling system clean so it can work at its most efficient.

That is why using plain distilled water along with a pint of rust inhibitor / water pump lubricant works so well in cars built before 1950. Most early cooling systems were designed to use plain water during the summer and antifreeze in the winter months (hence the name). Typically a early pre 1950's antique vehicle with plain water in the cooling system will run fifteen to twenty degrees cooler that the same antique vehicle with a 50/50 mix of antifreeze and water. Now you know why.

The radiator tubes in antique vehicles built prior to the 1940's are smaller in diameter as are the water passages in the engine block. That is why when you add a 50/50 mixture of modern antifreeze and water to an antique vehicle it often times will run hotter compared to using straight water. The circulation of coolant is slowed down with the addition of the thicker antifreeze.

When shopping for antifreeze, begin by reading the label to make sure it’s an IAT formula for older cars. You’ll likely find it to be green, the original color for traditional antifreeze. So when you look inside the radiator of your antique vehicle if you see green, chances are your antifreeze is of the IAT formula.

The next question is whether the antifreeze in your classic vehicle is still able to do its job, which is keep the inside of the cooling system clean. Color is a good starting indicator. Remember.... green is good, brown is bad. Brown means some of the the corrosion inhibitors in your antifreeze formula have broken down and are no longer able to keep the inside of your cooling system clean. Its time for a flush, and fresh antifreeze.

Next up you need to check your freeze protection. You can buy an inexpensive antifreeze tester (at any local auto parts store) and test the antifreeze in your cooling system to determine whether it’s still appropriately diluted for the protection you need. Generally, the best dilution is 50 percent water and 50 percent antifreeze will give you freeze protection down to minus 40 degrees. By taking a sample of the antifreeze from your cooling system you will know for certain what your freeze protection is.

Examples Of Inexpensive Antifreeze Coolant Testers...

A good flush at five-year intervals will keep your cooling components clean and working at their optimum potential. It is always a good idea to put a tag somewhere near your radiator cap with the date of the last flush and antifreeze replacement, and your freeze protection number. You should check your coolant level several times during a season to be sure you are not loosing any coolant.

The corrosion inhibitors in antifreeze will break down over time, which is why you should change it periodically.

If you cooling system needs a good cleaning Thermocure is what you need. It is available in the Parts section of the Fifth Avenue website under "cooling". There is also a Garage Tech "Tech Article" on this product an how it works. Just type in Thermocure in the search box on the of the Garage Tech Home page, and the article will magically appear.

The search box looks like this...

The search box looks like this...

One other option is to upgrade to Evans Coolant which is a lifetime coolant that freezes at minus 80 and boils at 370 degrees with no pressure in the cooling system and is non-corrosive. It is more expensive initially as compared to conventional antifreeze, but it is a lifetime coolant so in the long run you get better protection and zero maintaince for the life of the vehicle.

Evans Coolant is what we have been using in the Great Race cars since 1993 with good success. It is a lifetime coolant you only have to put it in once and it is non-corrosive and works especially well in antique vehicle cooling systems because it requires no pressure in the cooling system to work.

Just remember green is good... and be sure to read the back of the antifreeze container carefully. You want only the IAT formula!

You want to stay away from the long life formula, the OAT formula and the HOAT formula. Those are formulas for the modern vehicle with the alloy metals and have additives that will damage our early cooling systems. Follow these rules and life will be good!

11/9/18

The Penalty Of Leadership

I have a confession to make. People say I am a little eccentric in my thinking, and that is likely true. But I am a product of my youth and hanging out in all of the old automotive repair garages and car dealerships may have warped my young mind. Early on... I learned to figure out exactly how a part functions and to pay little or no attention to it's assigned application. More important was how the part functioned and what it was capable of and not the application the part was built for. Let me explain...

When I was about 14 years young, I learned from an old time mechanic (who lived and worked thru the depression) that is was more important to truly understood the function of a part and how it worked, over what the original application was. He drilled that idea into my young brain and unlike many other things, it stuck.

One of my first lessons occurred in his shop. He sent me over to sharpen a drill bit after casually explaining that two hexagon nuts held together will give you the correct angle to sharpen a drill bit within a couple of degrees. That explained the two 5/8 nuts sitting beside the bench grinder.) So I go over to his bench grinder and I can't find the switch to turn it on. "Look on the floor he says...see the dimmer switch inside that electrical box...step on it!" I did and the grinder took off. Who would have thought...?

I knew that this would result in yet another lesson. It did... but it was a good one about how an automotive floor dimmer switch worked and that there were two switches, one for High Beam and one for Low Beam and if one side burns out, the other side is usually still good.

So he used the good side of the dimmer switch to turn on his grinder, so if his hands were full he could still easily turn the grinder off an on! So simple and brilliant but I would have never figured that out on my own and looking back I had thrown out plenty of dimmer switches that had one side burnt out from my old Chevy pickups. I just did what everyone else did... and threw them out when one side quit working.

I got many more lessons from him during my younger years and all my lessons were all like that, he made it seem so obvious that eventually I began to think like he did, on my own.

That came in handy when I began to work on building a 6-volt alternator. I had experienced enough hard starting, yellowish dim headlights and dead batteries to last a lifetime. Due in part to my early education I knew how a generator charging system worked, that a generator did not charge at idle and low rpm, which was the reason for the dim headlights, hard starting, and dead batteries.

I learned that I needed to drive ten miles at highway speeds in order to give a generator charging system enough time to recharge the battery from one start.

In contrast... I knew that an alternator did charge at idle and low rpm, and that is why the lights were always bright, there was no hard starting or dead batteries with modern alternator charging systems.

So that is why it made perfect sense to me, to apply modern technology in reverse to fix a 6-volt electrical system.

All of the experts and engineer types I talked with, said I was crazy and to stop waisting my time and theirs. But I knew that if I could build an alternator for a 6-volt electrical system that worked as good as it did on a 12-volt system, my life and everyone else who owned a 6-volt vehicle, would have a much better life. It took about two years to figure it all out and to make my alternators manufacturing friendly. But I knew I was on the right track. There was no doubt in my mind!

Because there was no such thing as a 6-volt alternator before I came along I had two strikes against me as I began offering my 6-volt alternators for sale. First off, there was no such thing as a 6-volt alternator, till I came along, and second, the only proof I had that my 6-volt alternator actually worked... was that it worked on my 1951 Chevy Pickup.

So that is when I got involved with the Great Race. I needed some way to advertise my 6-volt alternators and I figured seeing is believing. I knew if my alternators worked in the Great Race application they would work on any other 6-volt vehicle application.

They did... and I got free advertising all across the county as antique car owners talked to the Great Race entrants who were only to happy to explain how my 6-volt alternator fixed their electrical problems. That is how I found Howard Sharp of Fairport New York which I still sponsor today, some 30 years later! Howard is my best spokesman and salesman. His three Great Race first place finishes give him plenty of credibility.

Meanwhile...despite the help from the Great Race, I truly felt like the odd man out for the first five years of selling my 6-volt alternators. I knew they worked, The Great Race teams proved they worked, and they had been featured in numerous car magazines but still it was an odd concept. It took a few more years before antique vehicle owners finally "got it."

Meanwhile...the Great Racers came back to me and said..." you did such a great job fixing our electrical issues, why don't you work on our cooling and fuel issues?" I accepted the challenge, figuring it had to be easier than the electrical.

It wasn't... but I figured out a solution to both the cooling and the fuel system issues, I knew exactly what the problems were... because I had witnessed them first hand, and I knew how to find a solution. I now manufacture over 40 specialized products to make all types of antique vehicles more reliable and fun to drive.

Today... thirty years later I am still involved in the Great Race, and still learning. I now have my 6-volt alternators in 23 foreign countries besides the United States and Canada. I remember how happy I was when I sold my first 6-volt alternator to a customer in Oklahoma...across the state line. I only sold about 40 alternators my first year, all in the state of Kansas, with that one exception. I thought I was finally on my way. Now some 30 years and more than ten thousand 6-volt alternators later, my 6-volt alternators are recognized around the world.

Right after I got my 6-volt alternator done and into production, I found this advertisement from General Motors Cadillac division dated 1915. It kind of put things in perspective.

The Penalty of Leadership

In every field of human endeavor, he that is first must perpetually live in the white light of publicity. Whether the leadership be vested in a man or in a manufactured product, emulation and envy are ever at work. In art, in literature, in music, in industry, the reward and the punishment are always the same.

The reward is widespread recognition, the punishment fierce denial and detraction. When a man’s work becomes a standard for the whole world, it also becomes a target for the shafts of the envious few.

If his work is merely mediocre, he will be left severely alone. If he achieves a masterpiece it will set a million tongues wagging. Jealousy does not protrude its forked tongue at the artist who produces a common-place painting. Whatsoever you write, or paint, or play, or sing, or build; no one will strive to surpass or to slander you unless your work be stamped with the seal of genius.

Long after a great work has been done, those who are disappointed or envious continue to cry out that it cannot be done. Spiteful little voices in the domain of art were raised against our own Whistler as a mountebank, long after the big world had acclaimed him its greatest artistic genius. Multitudes flocked to Bayreuth to worship at the musical shrine of Wagner, while the little group of those whom he had dethroned and displaced argued angrily that he was no musician at all.

The little world continued to protest that Fulton could never build a steamboat, while the big world flocked to the river banks to see his boat steam by. The Leader is assailed because he is a Leader, and the effort to equal him is merely added proof of that leadership. Failing to equal or to excel, the follower seeks to depreciate and to destroy, but only confirms once more the superiority of that which he strives to supplant.

There is nothing new in this, it is as old as the world and as old as the human passions of envy, fear, greed, ambition, and the desire to surpass. And it all avails nothing. If the leader truly leads, he remains the leader. Master Poet, Master Painter, Master Workman; each in his turn is assailed, and each holds his laurels through the ages. That which is great makes itself known, no matter how loud the clamor of denial. That which deserves to live, Lives. ©Copyright 1915 Cadillac Motor Division.

In the end the goal that I set for myself when I was twenty, had finally been reached. My goal was to learn how to make all types of antique vehicles more reliable and fun to drive. What I have learned preparing cars entered in the Great Race every year for thirty years, has taught me just that, and what I learned, I have applied to all types of antique vehicles to make them more reliable and fun to drive.

Bud Melby was my first Great Race customer in 1989, and became a good friend and mentor to me. He often said... "your legacy is the only thing you will leave behind, and you will be remembered not for how much money you had, or how big of a house you lived in, or how many antique cars you collected. Your legacy will be what you did to make the world a better place.

You legacy is built on the fact that you invented something, designed something, or improved something, that had a positive impact and benefit to the people who bought and used what you have created. Bud said..." your 6-volt alternators are an example of that... you improved the electrical system of my 1936 Cord making it more reliable and fun to drive. You changed the whole personality of that car for the better. I was not prepared for that much of an improvement from your 6-volt alternator. You exceeded my expectations. That will be your legacy with me, and everyone else that buys one of your alternators..."

I confess, I did not understand all of that legacy business when I was in my twenties, but now forty years later... it has become crystal clear. Thanks Bud!

11/1/18

Battery Tenders...What Kind To Buy...

I get asked fairly often about battery tenders, and what kind we use on the cars entered in the Great Race. Well... we have used the same brand for the past 30 years simply because they work. We have tried about every brand, the cheaper to the more expensive but have always come back to the Battery Tender brand because they are simple, they are durable, and they work.

First off we need to talk about why you should use a battery tender in the first place. A battery tender will keep your battery fully charged while your antique vehicle is parked in storage. If you get a good one it will compensate for any parasitic draw such as from car radio memory or an accessory that runs in the background. Their use is not limited to antique vehicles, they will charge and maintain any battery from your riding lawn mower to your 1950 Buick.

First off we need to talk about why you should use a battery tender in the first place. A battery tender will keep your battery fully charged while your antique vehicle is parked in storage. If you get a good one it will compensate for any parasitic draw such as from car radio memory or an accessory that runs in the background. Their use is not limited to antique vehicles, they will charge and maintain any battery from your riding lawn mower to your 1950 Buick.

The difference between a battery tender and a small trickle charger comes when your battery becomes fully charged. A trickle charger or small battery charger either charges or it doesn't... so it has no way to "Float" a battery which means just enough current output to keep the battery fully charged... but not overcharged or undercharged.

A trickle charger or small conventional battery charger turn on and off as a way to try and maintain full battery voltage. The result is the battery gets over charged then sits and becomes discharged then the battery charger begins to charge again. The constant charging and discharging shortens the life of the battery, and there is no way to compensate for a parasitic electrical load.

In contrast a battery tender provides a steady voltage that is just enough to maintain proper battery voltage so the battery is always a peak charge. A battery tender will not over charge a battery. That makes the battery last at least twice as long because it is not constantly being charged and then discharged. It is kept at a steady voltage. It also prevents any damage to the electrical system of your antique vehicle while it is in storage.

In contrast a battery tender provides a steady voltage that is just enough to maintain proper battery voltage so the battery is always a peak charge. A battery tender will not over charge a battery. That makes the battery last at least twice as long because it is not constantly being charged and then discharged. It is kept at a steady voltage. It also prevents any damage to the electrical system of your antique vehicle while it is in storage.

The technology of how batteries are manufactured has changed a lot in recent years (mostly for the better) and now many of the batteries you buy are the AGM or absorbed glass mat type (Optima) or a Gel battery. So now we need a battery tender that will charge all three types of batteries, the old school lead acid battery, the AGM type, and the Gel batteries.

While we are at it a faster charging rate would help with the AGM and Gel batteries which take a little more current to begin charging. It makes a conventional battery charge much faster as well, Twice as fast to be exact, as compared to the previous design Battery Tender.

The new Battery Tender shown above will also charge BOTH 6-volt and 12-volt batteries...so now you no longer need two different battery tenders, one for 6-volt and one for 12-volt. A battery tender should also come with the correct accessories including...

The new Battery Tender shown above will also charge BOTH 6-volt and 12-volt batteries...so now you no longer need two different battery tenders, one for 6-volt and one for 12-volt. A battery tender should also come with the correct accessories including...

You should expect to have the short leads in a wiring harness that you can attach to the vehicle battery that hide when not in use, then when you plug into your battery tender you do not have to open the hood to make connections. The wiring harness that comes with this battery tender is made so it only plugs in one way so you can't get the connections backwards.

You should also have a wiring harness available for your battery tender for temporary connections to charge a battery most anywhere.

Both types are included with the battery tender shown above. The warranty on this new Battery charger is 5 years. The AC cord is 6 feet long and the battery to charger cords are 2 feet long, which is long enough reach for most applications. If you are into the numbers game here is the physical size of the new Battery Tender

And the specifications...

I have only three of the original old school Battery Tenders left and all three are 12-volt. The 6-volt ones are all gone. So it you want a Battery Tender of the old school design you had better act fast.

If you have one of the old school design Battery Tenders, all of the wiring harnesses from your Battery Tender will work with the new design Battery Tender. If your old school Battery Tender is working fine might as well keep using it. But... when the time comes to upgrade you now know what you need to buy, and life will be good once again.

If you have one of the old school design Battery Tenders, all of the wiring harnesses from your Battery Tender will work with the new design Battery Tender. If your old school Battery Tender is working fine might as well keep using it. But... when the time comes to upgrade you now know what you need to buy, and life will be good once again.

10/24/18

Battery Cables 101

Know Your Battery Cable Sizes...

The biggest complaint that I hear from antique vehicle owners is " my antique vehicle will not start when its hot." This is one of the easiest thing to fix and involves one simple rule and a little common sense, so pay attention here!

First is the rule. The larger in physical diameter that your battery cable is... the more volume of current the battery cable will deliver from the battery to the starter with less electrical friction (resistance). In contrast the smaller in diameter that your battery cable is... the smaller the amount of current it will deliver to the starter from the battery, and the greater the electrical friction (resistance) will be.

My typical analogy is the difference between a fire hose and a garden hose. The water pressure (which is equal to the voltage) is the same on both hoses, but it is the extra volume of water carried by the fire hose that will put out the fire.

We know that the starter on your antique vehicle should not draw more than 150 amps when cranking over the engine. Your battery is at least 400 cranking amps even if you have the cheap one from Walmart, and if you buy the Optima from Fifth Avenue (with the 3 year free replacement warranty) you will have a thousand cranking amps!

So if your engine does not crank over when it is warm the problem is the current from the battery is not getting delivered to the starter...and what has that job...?

THE BATTERY CABLES !!

The next most important detail is the ground. If your battery ground cable is connected to the painted frame, greasy engine block, rusty water pump housing, or the painted firewall... how do you suppose the ground current will get back to the battery? You are expecting the current to travel through rubber motor mounts, paint, grease, and what ever else is blocking the path back to the battery. You can easily loose thirty percent of your starters cranking power from a bad ground path.

So..what you need to do... is replace both of your stock battery cables with one gauge cables (which is about cuban cigar size) and make the ground cable long enough so it goes directly from the battery to a starter mounting bolt or as close to the starter as you can get it. You want to be sure and clean off any paint or grease at the starter where the starter cable is bolted to the starter, because you want a clean metal to metal contact!

What you are doing is creating a direct electrical path between the starter and the battery so the current can't get lost between the battery and the starter.

I always put a toothed star washer under the bolt head at the starter ground to be sure there is a good solid battery ground cable connection.

Both Battery cables should be one gauge or larger.

OEM 6-volt battery cables were typically 4 gauge, and 12-volt battery cables were/are typically 6 gauge. In the lesson you learned at the beginning of this article I said bigger is better. You ALWAYS want use one gauge cables for BOTH the positive and the ground battery cables, and if it is a heavy electrical load application like an antique fire truck... I use 1/0 battery cables which are the same size as welding cables.

This is true for all 12-volt applications as well. Think about the electrical load of a firetruck with lights and sirens. Many fire trucks (even the newer 12-volt applications) will have dual batteries which means many more cranking amps available. In order to take advantage of that extra cranking power you need the 1/0 cables on hand to deliver the larger volume of current from the battery!

This is also true for drag race cars. How many drag cars have you seen with dual batteries in the trunk and the ground of both batteries is bolted to the floor of the trunk. That ground current from the trunk floor will need to travel to the starter then back to the battery. How is that supposed to happen with rubber body mounts, rubber engine mounts, paint, grease, and related blocking the current flow. Have the trunk floor undercoated or sprayed with trunk splatter does not help either.

We know that electricity is lazy and will take the path of least resistance so odds are about half or less of the cranking power from the two batteries in that drag car will actually get delivered to the starter which is why the car owner put two batteries in the trunk. Having a high performance motor only add to the starter's electrical load. Even with two batteries his car barely starts and the owner always wonders why?

Again...the simple way to look at this is you know that the starter should not draw more than 200 amps in a high performance engine application., You also know that a modern 12-volt battery will be at least 600 cranking amps. So two batteries results in 1200 cranking amps or more which is six times what your starter needs to crank over the engine. The weak link between those two batteries and the starter is the battery cables. You need one battery and a firehose instead of two batteries and a garden hose.

If that same car owner would run two one gauge cables to the front of the car and ground the battery ground to a starter mounting bolt he could eliminate one battery and the car would start way better than using the two batteries he has now.

It is common on high performance applications to have car owners treat the symptoms instead of fixing the problem. The problem is easy enough to identify....the engine is cranking slow because the current stored in the battery is NOT getting delivered to the starter! Most drag car owners will put a battery with 800 to a thousand cranking amps in their car with good intentions. With the wrong size battery cables and the poor battery to starter ground, that car owner cannot take advantage of his high performance battery.

The money making fix (for the aftermarket) is to sell the car owner a high torque or gear reduction starter for a couple hundred dollars, and or a high dollar electronic ignition setup for hotter spark, or a host of other goodies to fix the problem when in reality all that needs to happen is to install the correct size of battery cables.

The focus should be on fixing the problem NOT treating the symptoms. When the car owner figures that out his car will start better than it ever has... and his wallet will be a little fatter, because he did not buy the parts to treat the symptoms, which often times does not fix the problem.

This is true for all 12-volt applications as well. Think about the electrical load of a firetruck with lights and sirens. Many fire trucks (even the newer 12-volt applications) will have dual batteries which means many more cranking amps available. In order to take advantage of that extra cranking power you need the 1/0 cables on hand to deliver the larger volume of current from the battery!

This is also true for drag race cars. How many drag cars have you seen with dual batteries in the trunk and the ground of both batteries is bolted to the floor of the trunk. That ground current from the trunk floor will need to travel to the starter then back to the battery. How is that supposed to happen with rubber body mounts, rubber engine mounts, paint, grease, and related blocking the current flow. Have the trunk floor undercoated or sprayed with trunk splatter does not help either.

We know that electricity is lazy and will take the path of least resistance so odds are about half or less of the cranking power from the two batteries in that drag car will actually get delivered to the starter which is why the car owner put two batteries in the trunk. Having a high performance motor only add to the starter's electrical load. Even with two batteries his car barely starts and the owner always wonders why?

Again...the simple way to look at this is you know that the starter should not draw more than 200 amps in a high performance engine application., You also know that a modern 12-volt battery will be at least 600 cranking amps. So two batteries results in 1200 cranking amps or more which is six times what your starter needs to crank over the engine. The weak link between those two batteries and the starter is the battery cables. You need one battery and a firehose instead of two batteries and a garden hose.

If that same car owner would run two one gauge cables to the front of the car and ground the battery ground to a starter mounting bolt he could eliminate one battery and the car would start way better than using the two batteries he has now.

It is common on high performance applications to have car owners treat the symptoms instead of fixing the problem. The problem is easy enough to identify....the engine is cranking slow because the current stored in the battery is NOT getting delivered to the starter! Most drag car owners will put a battery with 800 to a thousand cranking amps in their car with good intentions. With the wrong size battery cables and the poor battery to starter ground, that car owner cannot take advantage of his high performance battery.

The money making fix (for the aftermarket) is to sell the car owner a high torque or gear reduction starter for a couple hundred dollars, and or a high dollar electronic ignition setup for hotter spark, or a host of other goodies to fix the problem when in reality all that needs to happen is to install the correct size of battery cables.

The focus should be on fixing the problem NOT treating the symptoms. When the car owner figures that out his car will start better than it ever has... and his wallet will be a little fatter, because he did not buy the parts to treat the symptoms, which often times does not fix the problem.

Here are examples of the diameter of Battery Cables. Notice the difference in diameter between the 4 gauge the 1 gauge cables. The smaller the number the larger in diameter the battery cable will be.

You can get custom battery cables made at most any full line auto parts store like Carquest or NAPA and they can build them any length with the ends you need to match your application. They can build them in the store while you wait. They do that for diesel truck and off road heavy equipment applications.

If you follow this simple lesson you will fix your hot start problem once and for all. While you are doing the battery cable upgrade it would be a good time to check out your starter to see what the brushes look like inside the starter and the bushings on either end of the armature.

The difference that battery cables and the proper ground makes to your starting will truly amaze you. It is hard to believe something this simple can make that much difference. And remember...you read it hear first!

And if you want to learn even more ways to fix your hot start problems and upgrade the performance of your antique vehicle's electrical system you can order a copy of my latest book entitled "Help My Car Wont Start When It's Hot! It can be found under technical publications in the "Parts" section of the website located at the top of the home page. It will be the best $15.00 you ever spent!

If you follow this simple lesson you will fix your hot start problem once and for all. While you are doing the battery cable upgrade it would be a good time to check out your starter to see what the brushes look like inside the starter and the bushings on either end of the armature.

The difference that battery cables and the proper ground makes to your starting will truly amaze you. It is hard to believe something this simple can make that much difference. And remember...you read it hear first!

And if you want to learn even more ways to fix your hot start problems and upgrade the performance of your antique vehicle's electrical system you can order a copy of my latest book entitled "Help My Car Wont Start When It's Hot! It can be found under technical publications in the "Parts" section of the website located at the top of the home page. It will be the best $15.00 you ever spent!

10/11/18

Airplanes and Hot Rod Tractors In Kansas

The boys built their first flying aircraft during the summer of 1934. It looked much like a redesigned piper cub, a popular aircraft of the day. The engine the boys chose for their airplane was a Szekely three-cylinder radial engine. While inexpensive, the Szekely was not known for its reliability. Nevertheless, building a flying aircraft proved that the boys could design and build a flying aircraft from scratch.

The Szekely engine proved so unreliable it was quickly replaced with a highly modified water-cooled Ford four cylinder automotive engine, which was mounted in an inverted position. The Ford engine was modified by the Funk brothers themselves, and proved reliable enough to power the next 60 aircraft the brothers built.

In 1940 the brothers went to the Akron business community and asked for financial help. They could no longer work out of the back of their grocery store. The community responded raising $78,000 in capital, and the Akron Aircraft Company was incorporated. The Funk's aircraft manufacturing business was moved to an old abandoned four-story schoolhouse on the northwest corner of the Akron Airport.

Production slowed in the later part of 1940 when it was determined the modified Ford engines required an excessive amount of maintaince. The Funk brothers immediately switched to 75 hp Lycoming air-cooled engines. Unfortunately, they would soon discover that the Lycoming engines also had a design flaw one serious enough that it caused the assembly line to be completely shut down for a time… until the problem could be fixed. During the shut down one of the creditors got nervous, pulled his money out of the company, and forced the boys into bankruptcy.

Help came from two Kansas oil field suppliers. Bill and Raymond Jensen of Coffeyville Kansas. As a condition of the financial bailout, the Jensen's insisted that the Funk brothers move the aircraft company to Coffeyville.

The Funk brothers were anxious to resume building aircraft so they agreed. Production began in Coffeyville in November of 1941. Three planes were built and shipped to South America before the bombing of Pearl Harbor halted private aircraft production.

A Funk Airplane Built In Coffeyville Kansas

After the Funk brothers found out they could no longer sell airplanes, they turned their efforts to farm tractors. In 1948, Ford tractor owners were looking for more horsepower. A standard Ford tractor was 30 horsepower and could pull only a two-bottom plow.

An Example OF A Funk 6 Cylinder Conversion

A Funk Flathead Ford Engine Conversion

In fact, Ford was preparing to sue the Funk brothers when several of the conversions developed rear end failures. Further testing showed that the Ford rear ends were defective from the factory. A compromise was worked out and Ford dealers became authorized to make the conversions at the dealerships.

The kits were ordered from the Funk Aircraft Company with either the 100 hp Flathead Ford V8's or the Industrial 6 cylinder engines. The original tractor 4 cylinder engine was removed and sent back to Ford in the same shipping crate as the conversion kit came in. Ford then sold the engines as replacement engines for industrial applications with full factory warranty.

The Funk brothers stopped offering conversion kits about 1953 and the company closed soon after. In later years, the Funk conversion tractors were held in low regard because the production had stopped and repair parts were difficult to find. Used Funk tractors became so difficult to sell that many were converted back to the original four cylinder engines. A fire in the Funk building in the early 1960's destroyed the records of the Funk Company. So nobody knows for sure how many tractor conversion kits were sold. It appears that the Ford V8 was the most popular conversion although in reality, there was not much horsepower difference between the two engines.

Today, the original Funk Conversion tractors are highly collectible; especially those with the Flathead Ford V8's installed. So popular in fact that you can again buy a conversion kit (patterned after the Funk kit) to put a Flathead Ford V8 into a Ford N series tractor. If you own a few acres in the country what could be more fun than a tractor / mower combination powered by a Flathead Ford V8? Add a pair of Fenton Headers along with a pair of Smithys… and mowing will never be the same.

Oh...and one last thing, in case you were wondering if a Lincoln V12 engine would work with the Funk conversion kit, the answer is yes. It worked in part because the back of the Ford V8 engine, and the back of the Lincoln V12 engine are the same, so the Funk conversion kit would also work with the Lincoln V12.

Of course things like the frame, steering rods, the hood, and a host of other things all had to be lengthened much more than with the V8 engine conversion, which would be no small task. The Funk Company did not offer a Lincoln V12 conversion, but if they did... this is what it might look like. The guy who built this one says his tractor will run 60 plus mph. Wonder how he know that...? Scary thought.

I remember seeing a few of the Funk tractors around when I was in grade school and most of those got converted back to stock. Some of the local tractor dealers even refused to take them in on trade. Had I been a little older I would have bought one and had some fun.

This story has appeared in Engine Builder Magazine and a host of other automotive publications. I continue to write monthly columns for various automotive publications highlighting automotive history. I will share some of the more popular stories here...stay tuned!

Of course things like the frame, steering rods, the hood, and a host of other things all had to be lengthened much more than with the V8 engine conversion, which would be no small task. The Funk Company did not offer a Lincoln V12 conversion, but if they did... this is what it might look like. The guy who built this one says his tractor will run 60 plus mph. Wonder how he know that...? Scary thought.

I remember seeing a few of the Funk tractors around when I was in grade school and most of those got converted back to stock. Some of the local tractor dealers even refused to take them in on trade. Had I been a little older I would have bought one and had some fun.

This story has appeared in Engine Builder Magazine and a host of other automotive publications. I continue to write monthly columns for various automotive publications highlighting automotive history. I will share some of the more popular stories here...stay tuned!

10/10/18

Chrysler Put A Hemi In What...?

So…you think you know your Chrysler history… and you can name every application Chrysler ever put a Hemi engine into. Well I got one I bet you never heard of. Chrysler like most automotive companies secured contracts during World War II to build tanks, airplanes, as well as guns and ammunition. Chrysler was no different than all the rest with one exception, the air raid siren. Chrysler earned the distinction during the war years of building the loudest most powerful warning device ever built. No company before or since has built anything like it.

Development of what would be later became known as the Chrysler Air Raid siren was started in January 1942. First attempts were built at the request of the Office of Civil Defense in Washington D.C.

The E.D.Bullard Company of San Francisco designed an engine driven centrifugal siren and submitted it for testing and certification. Chrysler got involved in part because the centrifugal engine driven siren offered by the Dullard company used their Flathead six-cylinder engine to power the siren. Despite extensive tests and modifications, the Bullard-design centrifugal siren could not produce the necessary volume of sound.

In earlier research, the Office of Civil Defense in Washington D. C. had determined that a minimum of 120 to 140 decibels of sound pressure at 100 feet, was the minimum requirement output for a warning siren. With the failure of the Bullard Company siren to meet the specifications, Chrysler was invited to a meeting in Washington D C, along with a few of the sound engineers from Bell Laboratories, to work on the problem and come up with a solution.

With Harry Fletcher of Bell Labs in charge, the engineers at Bell Labs went to work. This resulted a few months later, in the introduction of "Big Bertha" a huge centrifugal engine driven siren one of the largest ever built up to that time. The Bell Labs siren and was capable of 134 decibels of sound at a range of 100 feet. Now that the Bell siren design was proven successful, the Bell engineers drew up a series of specifications, using "Big Bertha" as a guideline, Chrysler was then awarded a contract to build the Bell designed and engineered air raid warning sirens.

The first version became known as the Chrysler-Bell Victory Siren. This first, siren, had a somewhat crude unrefined appearance, Despite its looks, it became certified by the Office of Civil Defense in March of 1942. One hundred twenty of these "Victory Sirens" were sold to 28 different cities among them New York City who bought (10) copies. The city of Detroit bought (20), as did the city of Chicago.

The Victory sirens sold for the tidy sum of $3,760 each in 1942 wartime dollars and were powered by a Chrysler straight -eight 324 cubic-inch engine that was rated at 140 HP. The government test results showed this siren with its two-stage blower was capable of producing a sound output of 134 decibels at a frequency of 430 Hz at a distance of 100 feet.

One of the problems with the early sirens is that the sound they produced was directional. To solve that problem the sirens were fitted onto a belt driven turntable that would rotate a full 360 degrees at 1.5 revolutions a minute. An operator was required to sit on a tractor type seat and control the operation of the siren and the direction of rotation, a job for which I am sure their were not many volunteers.

The second design of this siren built by Chrysler was much more refined than the first. Improvements in design also made the assembly of the sirens easier, faster, and less expensive. In the second design, the Bell name was dropped, and the sirens simply became known as the Chrysler Air Raid Siren.

The second design used the same 140 HP engine as the first design and the sound output was said to be the same. The second series was built from the middle 1940's up through 1951.

In 1952, a final and more advanced model was introduced. Along with a few refinements was the addition of Chrysler's new 331 cubic-inch, Hemi-Head V8, which produced 180 HP at 4600 rpms.

The latest design proved to be the best ever. It was by far the loudest at 138 decibels at a distance of one hundred feet at a range of 460 Hz. Best of all it was controlled remotely so no operator was needed to ride the siren and run the controls.

To put this Hemi powered air raid siren's output loudness into perspective the telephone in your shop rings at 80db while a city police car or ambulance measures120db at a distance of ten feet. Now imagine 138db at a distance of 100 feet… Yeeoooow!!

This design became the most popular and a couple of hundred were sold to larger cities across the United States. Besides their tour of duty for World War II, many of the sirens were again used during the cold war when the threat of nuclear war became very real in the 1960's.

While no examples of the first two siren designs are known to have survived, a few of the third design (which was built up through 1957) have survived.

The Siren Harry Barry bought and restored that was once located near the school where he grew up.

Harry Barry grew up in Pittsburgh Pa. area during the 1950's and he clearly remembered there was one of the third generation Chrysler sirens near his school. It was tested each month and Harry remembers that very loud distinctive sound.

In later years Harry became interested in sirens (no doubt influenced by his early childhood), and went back to see if the siren was still there next to his old school. It was and he bought it. He then went to work and restored it. He tracked down and bought one more, and knows the whereabouts of (6), more.

So the next time you are attending a car show and see a 1957 Chrysler cruising by... you may want to take a moment, and reflect on what might have been. Instead of that Hemi engine rumbling under the hood of that Chrysler, it could have ended up in service to our country.

Like Harry I also have an interest in and collect sirens. I have about 3 dozen sirens in my collection of all different shapes and sizes, the oldest one being from about 1926.

I do not have a siren in my collection as big as the one Harry has bought and restored but I can appreciate his efforts to track down and restore one of that size. The largest one I have ever owned was the one that was on top of our City Hall building when I was growing up. It was an old air raid siren from World War II. After the war it was used by the fire department. When the local fire department got a fire alarm they would turn on that siren to let all of the volunteers know of the alarm and they were to report to the fire station immediately. You could literally hear that siren for miles around so everybody got the message, and they often said it would wake the dead.

Later... when modern technology came along all the fireman got hand help radios and pagers so they no longer used the old siren. When it came time to repair the city hall roof after a hail storm the city decided the old siren needed to go away. They took sealed bids and I was the winner.

Soon after I learned that it ran on 3 phase 5 hp electric motor. I befriended one of the local city public utility workers and we tried it out on a Sunday afternoon.

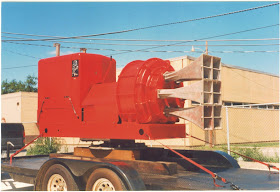

The World War II Siren from City Hall all 280 pounds worth. It is nearly five feet across and the rain cap on top looks like an army helmet from back in the day.

I knew the siren was loud on the top of city hall but when it was on the ground sitting on top of my car trailer in the alley... it gave new meaning to loud. After a couple of times, I had my fun, and the neighbors had made it clear they were not impressed with my siren. I eventually sold it to a small community in Oklahoma who wanted to use it as a tornado siren, a job it was clearly up to. With a population of barely 800 residents they clearly did not have much of a budget for storm warning devices, although like Kansas, they clearly had the need for one.

So in the end... I had my fun, got my money back, and there is a small town in Oklahoma who can now warn their residents of an approaching tornado. I have stopped in that small town a couple of times over the years to look at my siren perched on top of their City Hall building. I just smile to myself... it is in a good place and my neighbors couldn't be more pleased.

And I am still on the lookout for sirens to add to my collection. I am a little more selective now and leave the full sized ones alone.